LX Torana A9X: Too Good For Its Own Good?

At the 1979 Bathurst 1000 Peter Brock in his HDT Torana A9X hatchback was fastest in practice, took pole position, led the entire race distance with co-driver Jim Richards and set a new race record and lap record on the final lap, crossing the finish line six laps ahead of the next Torana with A9Xs filling the top eight places. Such a history-making result capped one of the most incredible eras of dominance in touring car racing.

Unfortunately, the A9X proved to be so superior to Ford’s venerable XC Falcon Hardtop it prompted a shell-shocked Ford to withdraw from the sport. By the end of the 1979 season, Holden realised that the A9X had been too good for its own good and the overall health of the sport and announced its shock withdrawal of support for the Holden Dealer Team. “GM-H has achieved a position where it has tended to dominate the sport,” GM-H explained. “We find ourselves competing against private entrants driving our vehicles.”

It had been a remarkable turnaround for Holden given that the A9X’s predecessor – the LH Torana sedan-based L34 - had suffered a humiliating season-long flogging by Ford in 1977. The L34 had exposed some serious durability issues in its early race outings in 1974 but by 1977 had been developed into a consistent race winner. However, it was inherently fragile due to various engineering compromises, highlighted by its feeble M21 gearbox and drum-braked Banjo rear axle assembly which were barely adequate for racing duties behind a powerful V8.

After the L34 claimed the first seven places at the 1976 Bathurst 1000, the complacency shown by Holden management on the eve of the 1977 season was understandable, even though HDT boss Harry Firth knew that Ford was gearing up for a big dollar factory attack with Allan Moffat and had been lobbying the GM-H top brass to respond with urgent upgrades to the L34.

Holden’s smug confidence was shattered as soon as the 1977 touring car season commenced, as Allan Moffat and his new team-mate, ex-HDT star Colin Bond, unleashed a barrage of Ford firepower under US tuning whiz Carroll Smith that had not been seen since the GT-HO days. It was the first time the L34 brigade had faced the formidable force of a sustained big dollar two-car Ford factory attack, for which it had no defence.

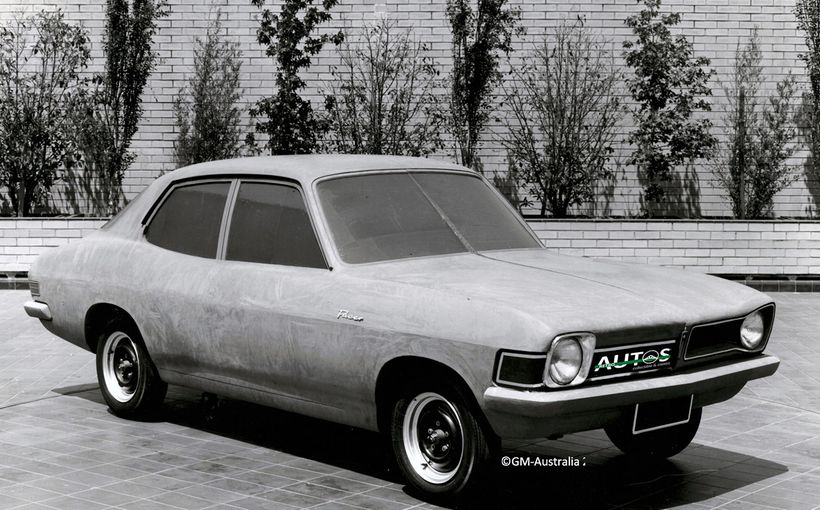

The shock of Ford’s sudden superiority made an L34 upgrade top priority, but GM-H faced a race against time to get its LX-based Performance Vehicle Package (option code A9X) tested and built in sufficient numbers (minimum 250 road-registered vehicles for CAMS homologation) to be ready in time for the all-important Bathurst 1000 in October.

A9X: What made it great

Holden released its LX Torana series in February 1976 which externally was a mild cosmetic facelift of the LH model introduced in March 1974. However, the big news was the addition of a new sporty three-door hatchback body style to compliment the sedan.

The new hatchback offered just two models – SL (equivalent to SL sedan trim) and SS (equivalent to SL/R sedan) while the LX sedan was available in a choice of S, SL, SL/R and top-of-the-range SL/R 5000 models. The models of most interest to muscle car fans were the SL/R 5000 sedan and the SS 5000 (aka SS 5.0 Litre) hatchback equipped with the company’s locally designed 5.0-litre (308 cid) V8 engine.

Nine months later, in November 1976, Holden introduced its new Radial Tuned Suspension (RTS) to the Torana range, initially in the Sunbird model and all six and V8 models by mid-1977. The overall handling and safety of Toranas fitted with RTS was vastly superior to any previous offerings.

It was these three key ingredients - the LX SL/R 5000 sedan, SS 5000 hatchback and RTS - which would lay the foundation for one of Australia’s greatest competition muscle cars.

Put simply, the key objective with the A9X was to work through the L34 from front to back and fix all of its weaknesses. HDT boss Harry Firth built a prototype based on an early LX hatchback which incorporated all the improvements over the L34 required for racing. It was then up to GM-H chassis engineer Ray Borrett and his team to bring race and road requirements together into a cohesive road-registerable package. Borrett, who together with former Opel chassis engineer Peter Hanenberger was heavily involved in the development of RTS, explained this process to AMC magazine in 2008:

“He (Harry) built what was required from a racing point of view and then we had to look at what we could do with that from a (road car) production point of view. When you talk about the fiberglass flares on the guards and their attachment methods, trimming up the sheetmetal underneath the bolt-on flares, hood scoops, front and rear spoilers and what have you, there had to be a few compromises involved in that, but I think we pretty much achieved the sort of thing Harry was requiring as a race car.”

Engine

Road going versions of the A9X were equipped with the ADR-compliant L31 version of the 5.0 litre V8 which with its 161kW (216bhp) and 400Nm (295 ft/lbs) provided sparkling performance given the car’s light 1.2 tonne kerb weight and athletic power-to-weight ratio.

For racing, the well-developed L34 V8 with around 400bhp carried over to the A9X but with numerous durability upgrades requested by Firth including thicker and stronger cylinder blocks, camshafts, crankshafts and forged pistons. It also got improved breathing (see bonnet scoop).

To address the L34’s overheating issues in competition, the A9X road and race cars were specified with a new heavy-duty radiator and coolant overflow/recovery system. A Davies Craig thermostatically-controlled electric cooling fan replaced the old belt driven unit, which had a nasty habit of throwing fan-belts if over-revved on down-changes and also contributed to minor power losses.

Gearbox

All A9X road cars were fitted with the M21 four-speed gearbox shared with the L34, but for racing Holden gained approval to use the much stronger Borg Warner T10 by listing it as an alternative gearbox under factory option code MC7. Although it was listed as a dealer option, the T10 was a race-only application as it required a different clutch, tail-shaft assembly, gear-shift mechanism and gear-stick location. To provide the extra floor clearance required for the T10’s shifter arrangement, a section of the Torana’s transmission tunnel had to be cut out and a special adapter plate or ‘blister’ supplied by the factory welded in its place.

Rear axle

To replace the fragile ‘Banjo’ unit used in the L34, the A9X was blessed with a new rear axle assembly that married the Holden One Tonner’s much larger and stronger 10-bolt Salisbury limited slip differential with shortened HZ GTS axle tubes, shafts and (for the first time in a Torana) rear disc brakes.

Suspension

Although based on the RTS-equipped LX SL/R 5000 sedan and SS5000 hatchback, with the same track widths as the L34, the A9X suspension was uniquely designed with the dual role of road driving and racing in mind.

New rear suspension pick-up points and extra diff clearance were provided by a special floor patch (from the upcoming UC Torana) which was welded into the LX floor pan in production. Holden also homologated the entire A9X front cross-member and suspension assemblies as a single unit, with revised geometry and hardware changes unique to the A9X. The steering rack assembly was also unique to this model and solidly mounted to the cross-member for sharper response.

Borrett: “The A9X suspension was a fairly major departure from the production RTS stuff in terms of geometry, pick-up points etc so that when the car was in full race trim the geometry was still as good as you could get. It was to do with the altered suspension height so that once you lowered the car (for racing) it kept the camber curves, castor and toe changes right. The front and rear suspension of the A9X were unique to that model and were never used in anything else. They were a pretty special car.”

Brakes

The A9X road cars featured terrific braking performance with Holden HX front disc brake assemblies (276mm ventilated rotors) and HZ GTS rears (293mm solid rotors) clamped by single-piston calipers. On the race cars these components were upgraded with more specialised racing hardware featuring much thicker ventilated rotors and multi-piston calipers.

Wheels

The A9X road cars were equipped with 14 x 6-inch HQ GTS-style steel rally wheels with a unique off-set. Race cars used a variety of lightweight one-piece or composite racing wheels up to 10 inches in width, fitted with even wider tyres which put a massive amount of rubber on the bitumen.

Fuel tank

Standard road tank was only 55 litres, but race cars were fitted with custom-made bladder-filled aluminium fuel tanks with more than double that capacity for long stints at Bathurst. To lower the centre of gravity these ‘drop tanks’ were mounted below the boot floor for optimum handling and to get as much weight hanging behind the back wheels as possible for maximum traction.

Bodywork

The Torana A9X in road-going form was a bare-boned race homologation special and it certainly looked the part, with several additions to the standard LX sedan and hatchback bodies designed by Holden styling chief (and resident petrol head) Leo Pruneau purely for competition use.

These included big fiberglass wheel arch flares to shroud the 10-inch wide racing wheels and tyres. The front flares were carried over from the L34 but the rears (which also looked like L34 parts) were substantially wider to cover the bigger race tyres the A9X could use thanks to its much stronger Salisbury rear end.

The A9X’s front spoiler was also an L34 item with the addition of a pair of ducts (another box ticked on Firth’s wish-list) mounted behind the lower intakes to feed cooling air directly into the front brakes. The sedan’s rear spoiler was also from the L34 parts bin but the hatchback featured a new three-piece item (to allow the hatch lid to be opened and closed) that not only looked great but also seemed to work well in aerodynamic terms.

One of the A9X’s most prominent visual features was the huge reverse-facing bonnet scoop which covered a large rectangular hole cut into the bonnet. This was another request by Firth to allow more room to experiment with new induction systems, insulate the carburettors from power-sapping engine bay heat and allow them to breathe cool, dense air from the high pressure aero zone at the base of the windshield to produce more power. Ask and ye shall receive Harry!

Production

A9X production commenced on September 1, 1977 and a total of 405 road cars were produced, 100 of which were hatchbacks.

All were built on Holden’s vehicle assembly line at Dandenong in Melbourne under Plant Manager Colin Lewis and Production Control Supervisor Mike Prowse. The fiddly off-line work like fitting the bolt-on wheel arch flares, spoilers and bonnet scoops was completed at the Bill Patterson-Cheney Holden dealership in Ringwood. To marry these two production processes, partly-finished cars were trucked from the plant to the dealership in batches before being returned to the plant for final checks and shipment to dealers.

In addition to the 405 road cars, the Dandenong plant also produced another 33 hatchbacks and up to a dozen sedans as rolling shells purely for race teams. Unlike the road car production which was mostly sedans, the factory was clearly pushing the new hatchback for the track. Its three-door bodyshell offered more torsional rigidity than the sedan and GM-H sales guru John Bagshaw, who loved the look of the new body style, wanted it to take priority as the corporate race car.

These race-only offerings have become known as the ‘GMP&A cars’ because for the first time a car was invoiced as a single part (like an air filter, spark plug etc) through General Motors Parts & Accessories. They were not fitted with compliance plates like the road cars, with each instead being supplied with a unique GMP&A body tag.

The GMP&A process was designed to reduce the amount of time required by race teams to build an A9X, so these rolling shells were supplied without joint sealants, sound-deadening compounds and unnecessary brackets to save weight. They also received extra seam welding and spot welds for greater rigidity, blind retaining nuts for bolting-in roll cages, driver’s seat-belt harnesses etc and (when requested) installation of the floor blister for the T10 gearbox. These production line processes were greatly appreciated by time-poor mechanics.

Racing the A9X

Holden teams faced an incredibly tight turn-around time in getting the new A9X onto the race track in 1977, given that production started on September 1 and its first scheduled race appearance at Sandown Park for the annual Hang Ten 400 was only 10 days later!

The A9X was rushed into active duty yet Peter Brock still managed to give it a dream debut victory, driving a Bill Patterson Racing hatchback which had just been completed in time for the start of official practice.

However, the A9X’s immediate success at Sandown was not a true indicator of its competitive strength at that time, as the dominant Moffat Ford Dealer Team Falcon XC hardtops had both suffered unusual problems in practice and the race that kept them out of contention for a win.

As expected the Moffat team re-grouped and hit Mount Panorama three weeks later with such momentum that the new Toranas, which were still critically short on track development time, were steamrolled by Ford in a crushing defeat on the Mountain.

Even though Sandown winner Brock displayed ominous speed in qualifying to steal pole position from the factory Fords, his blue and gold A9X was hobbled by rear tyre clearance problems during the race that dropped it out of winning contention. The famous Moffat/Bond two-car formation finish that resulted, more than a lap ahead of the first Torana, left Holden executives tasting bile.

Not surprisingly, such public humiliation only fired up GM-H to retaliate with brutal force. By early 1978, the A9X had been well and truly sorted during the off-season, the highly regarded John Sheppard had taken control of the Holden Dealer Team after Harry Firth’s retirement and The General’s favourite son Peter Brock had returned to the factory team after a three-year absence.

Backing up the two factory cars of Brock and John Harvey were numerous well-prepared A9X hatchbacks for top gun privateers like Bob Morris (Ron Hodgson Racing), Allan Grice (Craven Mild Racing) and Pete Geoghegan (Bob Jane Racing Team) among a host of others.

The result was ‘scorched earth’ superiority over a crumbling Ford opponent that probably wished it had never provoked the roaring lion. The A9X’s long list of wins from its two and a half seasons of competition included the 1978 and 1979 Australian Touring Car Championships, 1977/78/79 Sandown 400s, 1978 and 1979 Bathurst 1000s and 1979 AMSCAR series.

Highlighted by the record-smashing six-lap victory by Brock and Richards at Bathurst in 1979, it’s no wonder the A9X is so revered by enthusiasts today. It was, quite simply, the ultimate Torana.