On the night of the 22nd September 1944, Alf Berry, a fitter Motor Vehicles Trade Group One with the Australian Electrical & Mechanical Engineers 109 Brigade workshops disembarks from a liberty ship, the Ann McKim onto the small Nissan Island off New Guinea.

Alf had served in Darwin during the Japanese bombing raids and travelled to Cairns before sailing on the Duntroon to Lae and then up to the Wau Valley and Milne Bay. The journey to Nissan Island had occurred during a huge storm that whipped the sea up in to fifty feet swells that saw the propellers of the ship shuddering up out of the water before plunging back down in to the sea. With quarters down in the rear hold and aware that the all-welded ships were known to break up in heavy seas it was a great relief to finally have land under foot.

With a day of rest it was time to explore the island which had seen its native population evacuated to another island. The Japanese had taken control of the island and were defeated by the New Zealand Army but were still in nearby areas. One of the first places Alf passed was the rubbish dump in which lay the remains of a Villiers-engined two stroke motorcycle with crankcases, three speed Albion gearbox and clutch still in the remains of the frame. Alf dragged it out for a closer inspection and place it under some nearby bushes. There were also some long lengths of two inch flat iron dumped there.

The following evening Alf went for a stroll in the other direction towards the airstrips. The island had a large lagoon in the centre that served as a base for the American Catalina aircraft that came up onto the land for maintenance but used the lagoon for take-offs and landings. Beside the main airstrip was a graveyard of damaged aircraft and trucks and further along towards the end of the runway was the bomb area where the bombs were primed and put on trolleys before being loaded on to the Mitchell bombers.

Alf stopped to chat to the Americans working here when one exclaimed to another chap “you’re not changing the oil in the motor again?” and laughed. Sharing the joke revealed that one had drained a compressor motor of oil and gone off to get some new oil. The other started up the motor unaware it was dry of oil and naturally it wasn’t long before it stopped functioning. The seized motor was quickly replaced by a new one from the Q store and the old one lay at the base of a tree. Alf went over to have a look at it and was told he could have it. Being interested in all things mechanical Alf thought he might take it back and dismantle it for something to do, and after an offer of a Jeep ride, Alf and motor returned to camp and by the following evening the motor was in pieces. Only the piston skirt had seized on the bore - just enough to stop the motor so with some work using a fine file and emery paper the piston and bore were cleaned up and the motor reassembled. It was a five horsepower Wisconsin engine that had a built-in clutch on the drive side and ran a good impulse start magneto which in this case had been removed and handed in at the Q store. Wanting to see if the motor would now run Alf visited the U.S. Q store to retrieve the magneto only to be told that you had to have a requisition form to get anything out of the store. Obviously an Australian was not going to get an American form but the chap then went on to describe that “you need to unscrew a big plug on the outside of the casing and turn the motor gear until two marked teeth showed and then fit the magneto with its marked tooth going between the two marked teeth on the other gear. Just like the one on the compressor down there,” he said with a grin and winked at Alf.

By some strange coincidence the magneto off the compressor “down there” vanished that evening and someone must have had the appropriate form as it was functioning again the next time Alf visited. With a magneto soundly fastened to the flange on the motor by three nuts Alf’s motor was now running, but what do you do with it?

Twenty-two year old Alf had been a keen motorcyclist before the War and dabbled in Scrambles and Grass Track events in his home town of Horsham (Victoria) and the Western District. An article in a magazine that belonged to an American Sea Bee gave him the idea to build a motor scooter and so a treasure hunt began. The Americans donated two tail wheels from the wrecked Corsair aircraft beside the runway, the rubbish dump was revisited and the Albion gearbox, lengths of flat iron and some angle iron found its way back to the workshop. Corsair Valve springs from the radial engines would provide suspension and to get drive from the motor to the gearbox another aircraft gave up some chain and sprockets from a cockpit cranking handle.

While delivering a despatch to the American HQ on a BSA M20, an Australian Don R had parked the machine and while inside the building an American in a big 10 wheel GMC fully loaded truck backed over the poor BSA, crushing it. The driver jumped from the truck and thought the sight of the mangled Beeza hilarious until he was informed that he was grounded and the cost of the replacement would come out of his salary. The wreck was returned to the Australian workshops and two days later a crate arrived with a new WLA Harley Davidson inside; a replacement from the Americans which was then painted the same as the BSA.

The only things to be salvaged from the BSA were the rear brake drum and brake assembly, gearbox sprocket, cables, petrol tap and chain.

With the assistance of the workshop blacksmith the Wisconsin motor was placed on the ground with a wheel behind it and the gearbox in between them. This arrangement appeared too long so Alf raised the gearbox up behind the motor and thought this would work if the petrol tank on top of the motor was removed. Marks were then scratched on the ground down both sides and across to form the basis of a frame that was measured up and formed from the flat iron with angle iron welded across in front of the motor to enable the outer frame to pivot on Chevrolet engine mounts cut in half, and utilising the Corsair valve springs at the back for suspension. The brake drum was bolted to the rear wheel with spacers and the frame was drilled and slotted to allow for the axle mounting, chain adjustment and brake plate anchor rod.

The motor was mounted on a plate welded to the inner frame and the gearbox was raised behind it to clear the rear wheel. With the inner frame complete now came the outer frame again using flat iron with angle iron cross braces the front frame rails were heated and brought up to be welded to a front tube steering stem that had been made up and machined to take two tapered aircraft roller bearings. The pivot between the inner and outer frames used the front rubber engine mount from a GMC truck, cut through the middle and fitted to the inner frame in front of the motor in the angle iron cross brace with two mountings at the rear at the corners to hold the radial engine valve springs with softer springs at the top to dampen the rebound.

The front forks were made from steel tubing with a brace out front for strength and trailing link suspension using two side-valve Ford V8 valve springs each side with hand brake rods and fittings, together with a clevis pin pivot at the bottom from an old truck. Bolts were welded in to the top of the fork tubes to mount the handlebars which were made of tube and held on by two nuts. A long cable was needed to work the made-up right handlebar twist grip so it was back to the plane graveyard where a control cable was located. The brake pedal, which was made of tube and flat iron was mounted in the front floor of the frame with a cable to the back wheel brake made up from the clutch cable off the BSA.

A tube frame was made for the seat, a rubber pad covered with a thick raincoat, and welded in place with a one gallon metal container for a fuel tank. An exhaust was made to take the gases out to the rear of the scooter.

It was November 1944 when Alf put oil in the gearbox and petrol in the tank and used the folding crank handle to fire up the motor. When the engine revs were brought up from idle the centrifugal clutch in the motor would work, and the chain to gearbox worked.

A spanner was used to turn the gear change shaft to first gear and Alf had his first ride around the workshop area.

On the air compressor, the carburettor linkage was worked through a control box by air pressure in the tank and from start up would pump up to 90 PSI. The air pressure would then close the throttle back to idle on the motor and the clutch would release and stop turning the compressor until the air pressure dropped back to 40 PSI. Then the throttle would open in the carburettor allowing the motor to rev up with the clutch engaging and turning the compressor again, completing the cycle. Alf found it worked on the scooter the same way by opening or closing the twist grip and needless to say the sight and sound of the scooter had many guys lining up for a ride.

Not yet finished, Alf got busy and made up a gear change lever on the front right side with a rod going back to an arm on the shaft of the gearbox and requiring a couple of alterations in length to get it working properly. Simply by closing the throttle the clutch would release allowing the next gear to be selected.

Alf set about making some bodywork using an alloy aircraft cowling which was cut to shape for a front guard and other alloy formed a panel in front of the seat with wire mesh for engine cooling. Side panels were added with more mesh where the engine cooling fan was located and a hole for the crank handle.

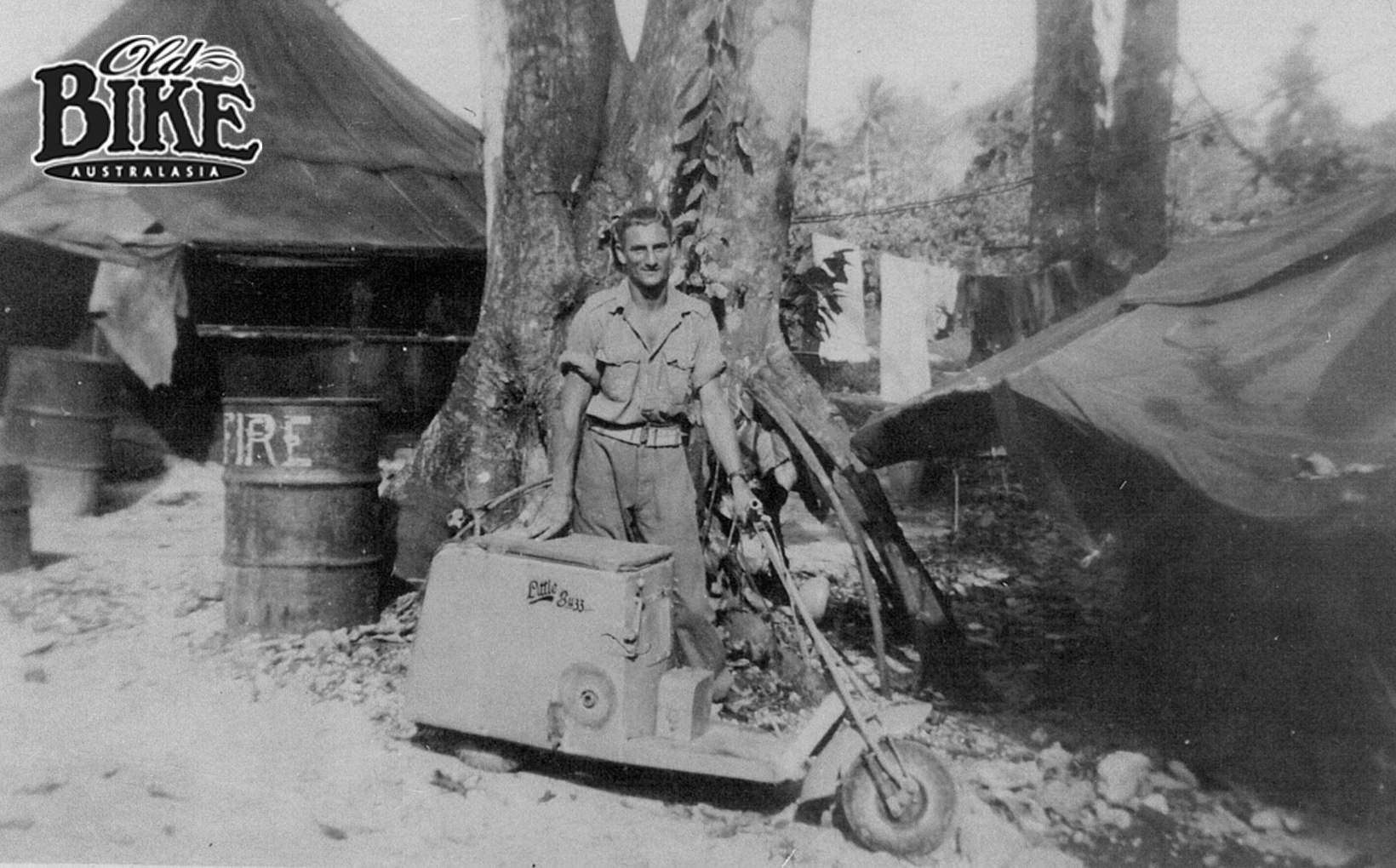

A blackout driving light was fitted as a headlight after removing the metal front and top shield and a tail light came from the same truck. The signallers used small 6 volt batteries and carried them in a light metal casing so one of these was used to work the lights as there were always small petrol engine battery chargers sitting on the ground. A paint brush and can of Navy grey paint completed the job with the painter practising his sign writing skills by adding “Little Buzz” to both side panels and by the end of November 1944 the job was done.

A large fuel tank belong to the American 553rd Sea Bees, located at the top end of the airstrip provided an unending supply of fuel and on one refill Alf was questioned about the origin of the scooter by some pilots. They jumped in their Jeep and travelling beside the scooter on the edge of the airstrip measured the scooter’s speed at 55 mph and on the run back with a pillion at 48 mph.

Alf became a regular visitor and rides on Little Buzz were traded for cigarettes, Coca Cola, food and best of all, eight “unofficial” flights in Mitchell Bombers bombing areas around New Britain and Rabaul. Many enjoyed the experience of a ride around the islands roads on this little scooter.

The time came to depart Nissin Island and travel by ship to Bougainville. Major Grimshaw a grumpy old man, had made it known during construction of the scooter that it would not be leaving the island and despite Lieutenant Smith’s best efforts to stow it away in the electrician’s work truck, it was discovered during the Major’s inspection and unloaded. The Lieutenant had also been a regular rider of Little Buzz.

Alf rode it down to the airstrip which had been evacuated by the Americans and the only person there with any money was a New Zealand aircraft instrument technician who purchased Little Buzz, certain that he would be able to take it home after the war. Names and addresses were exchanged but Alf lost the piece of paper and never heard from the new owner and has often wondered what became of his little machine.

Protect your Classic. Call Shannons Insurance on 13 46 46 to get a quote today.